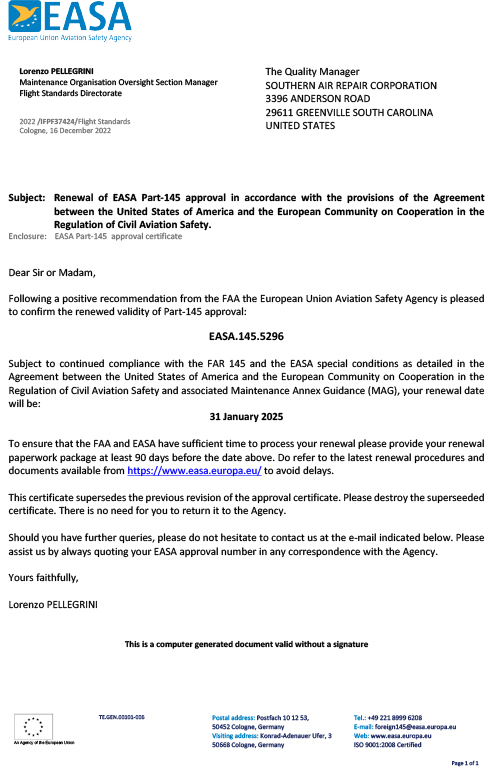

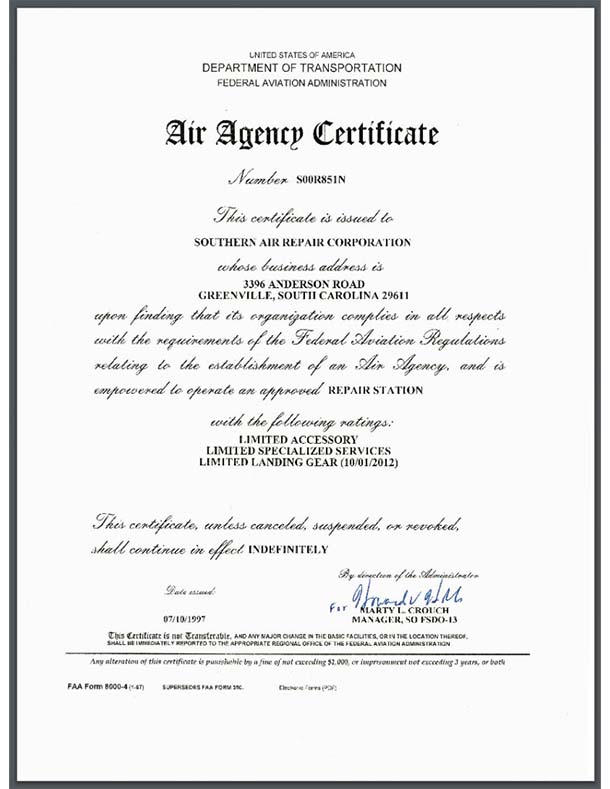

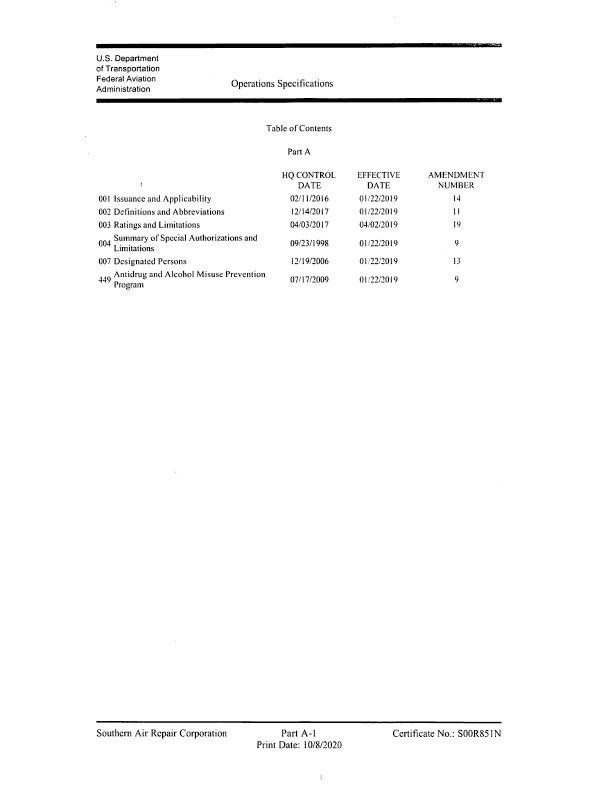

Here at Southern Air Repair, our team brings Innovative Engineering and Aviation Machining to a whole other level, including our Welding and CNC experience to accomplish our component piece part repairs. Southern Air Repair was established in 1997, by two aviation pioneers looking to better serve the airline industry. First located Coral Springs, Florida, we made our final frontier by moving the industry to Greenville, South Carolina. This year, we celebrate over 25 years of excellence while servicing airlines, regional carriers, and 145 repair stations with the highest level of experience and quality.

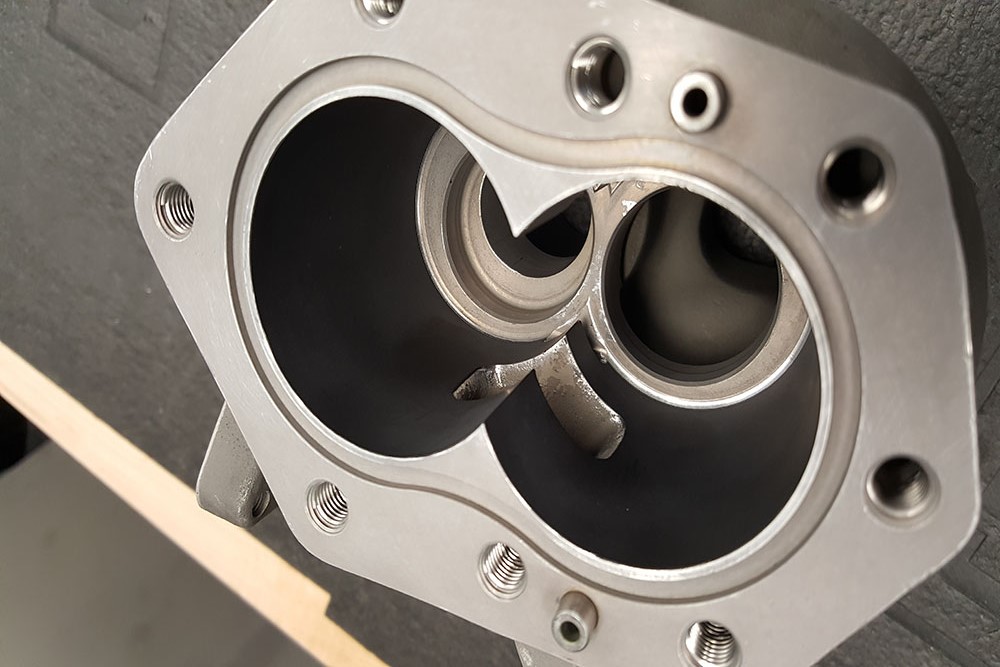

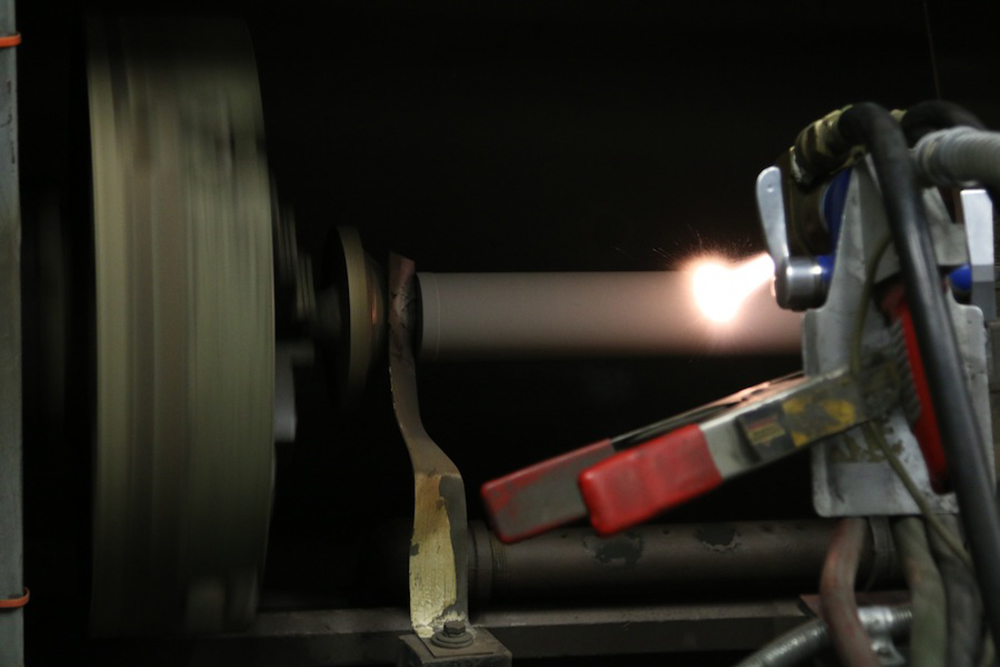

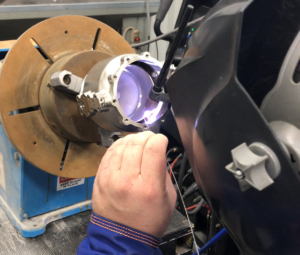

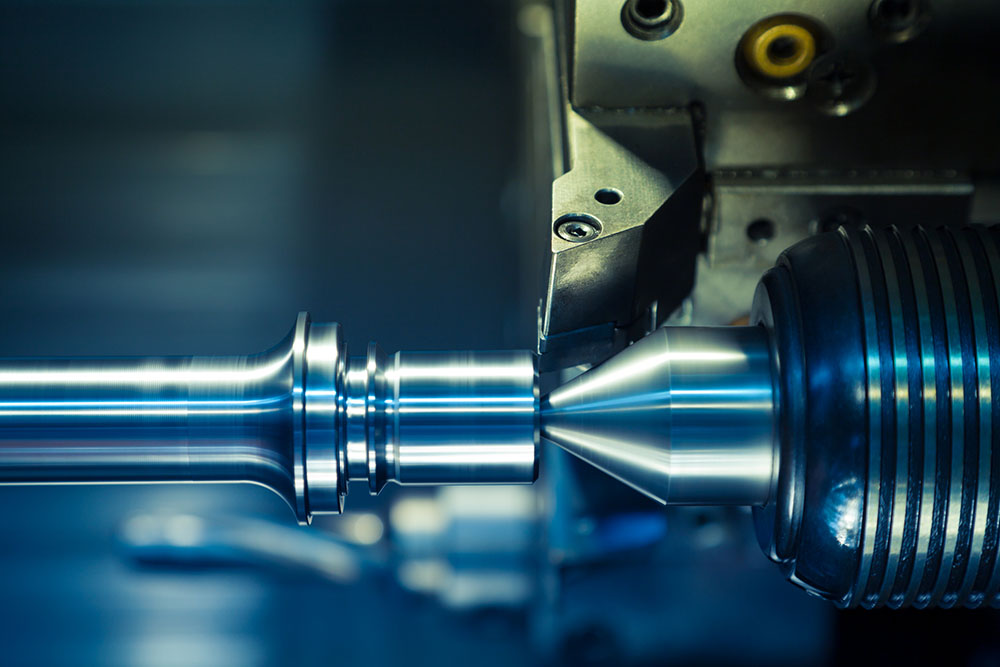

Our mission is to take non-serviceable/scrap accessory parts and reclaim them to airworthy condition. This process reduces BER’s, turnaround times, and has a high success rate while competing with prices of new manufactured parts. We have established a reputation for accomplishing repairs that were once considered nonviable, which has saved our customers millions of dollars in replacement costs.

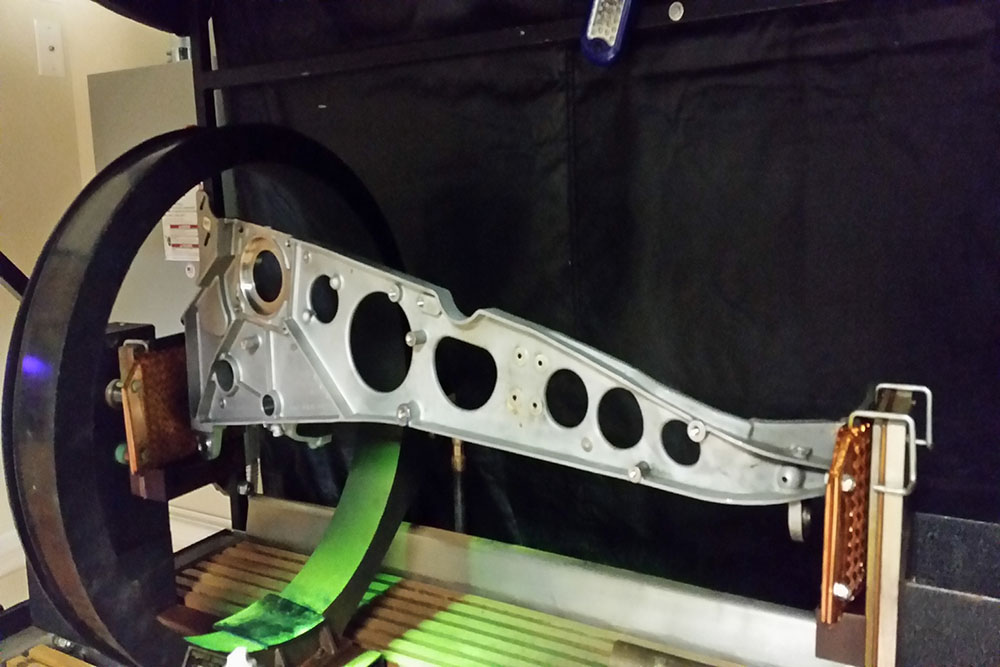

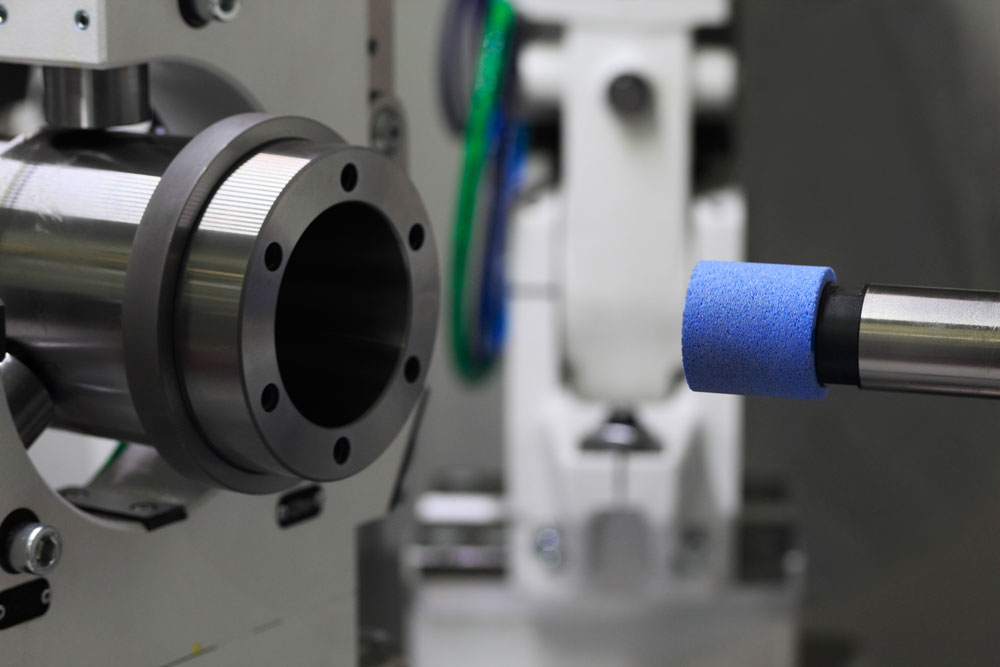

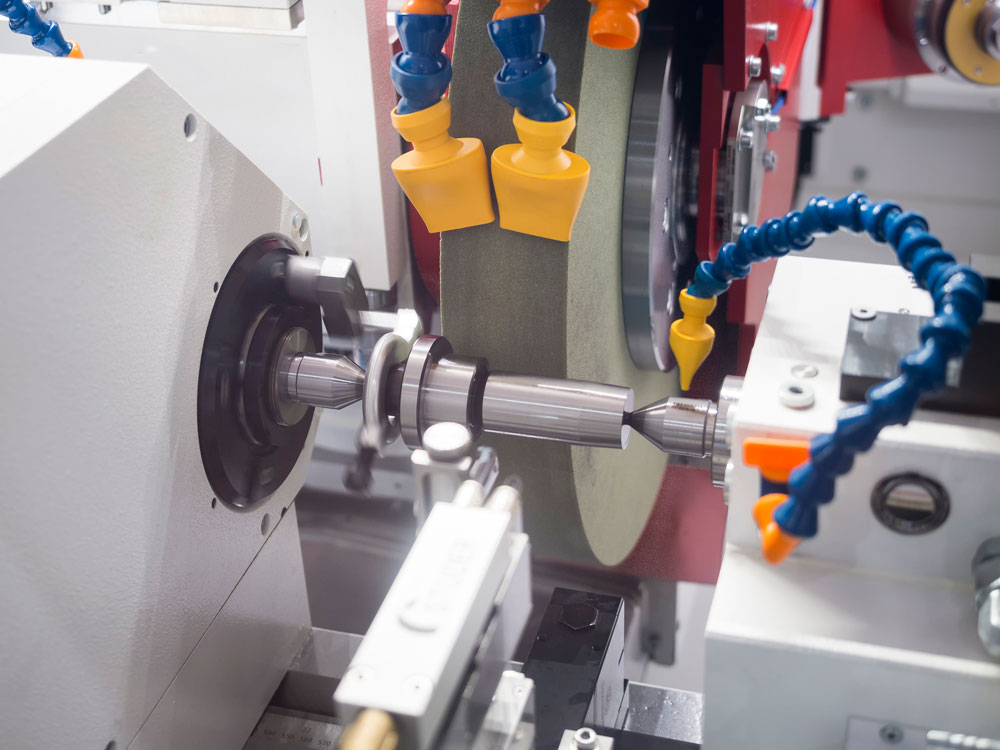

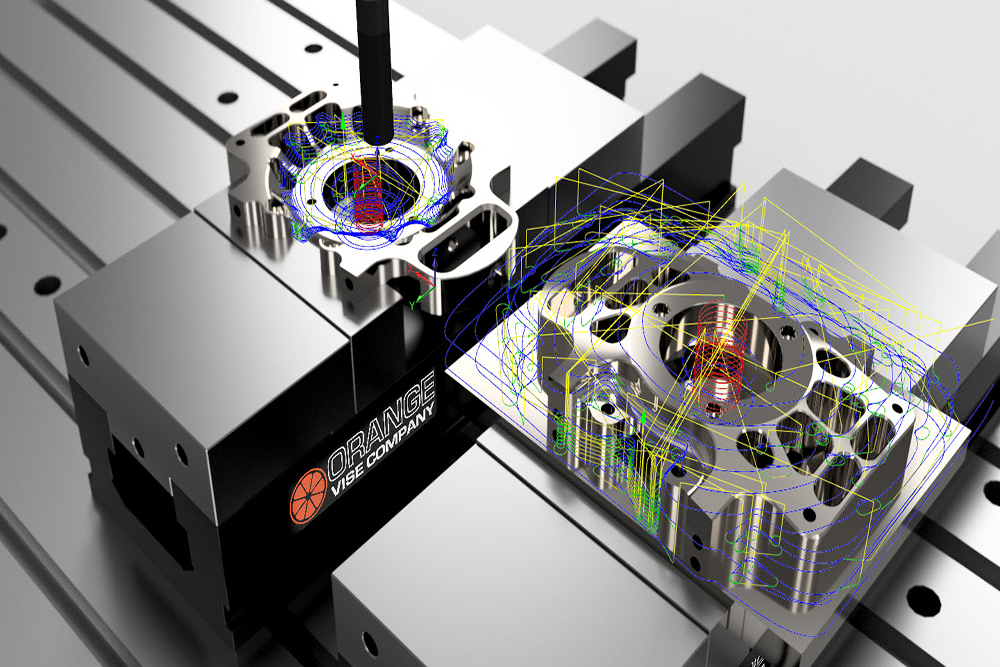

Southern Air Repair has developed over 450 FAA approved component piece part repairs with concentration in CSD’s, IDG’s, Fuel and Pneumatic accessory parts. We offer full CNC lathe and mill support. Recent jobs include Gulfstream Wifi antenna mount, ATR-72 flap cam guide, IDG rotor balance weight holder and Axial fan housing liner.

We would love the opportunity to show your company the high success rate that we maintain with our current customers.